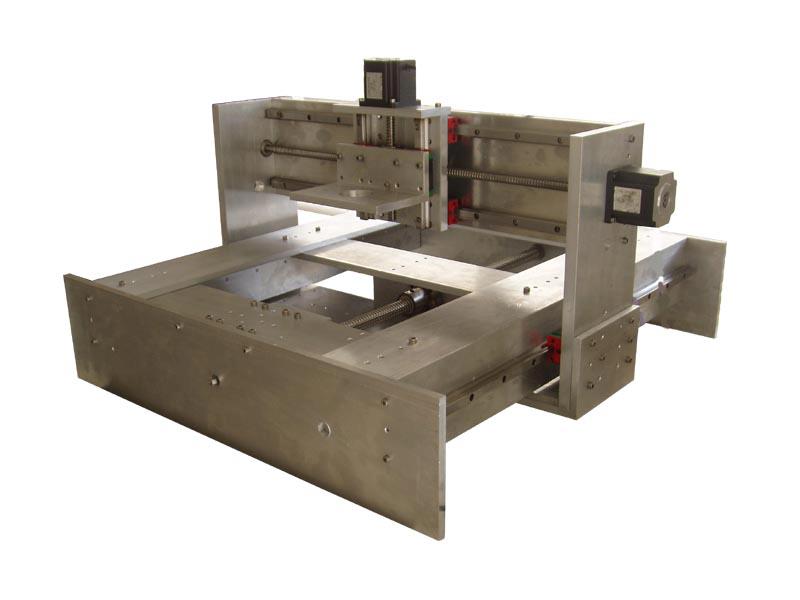

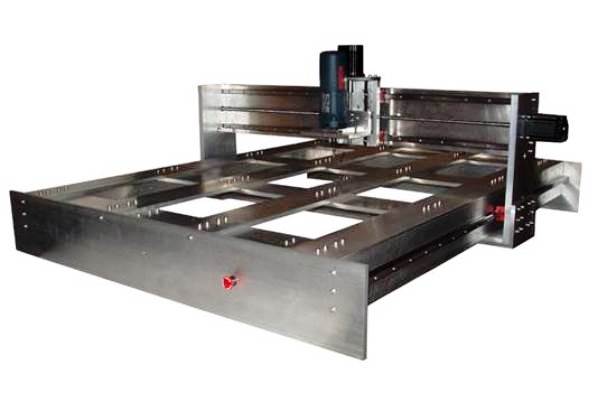

CNC CHARACTERISTICS

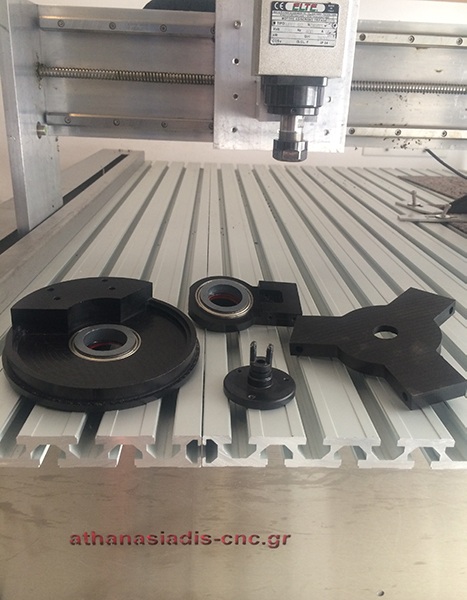

CNC (Computerized Numerical Control) is the operation of a machine through a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite material) to meet specifications by following a coded programmed instruction and without manual intervention. They operate automatically, using programming codes generated by suitable software. They are distinguished for their very high performance in terms of processing speed and the quality of the final product, due to their high precision. These advantages make them ideal tools for mass production.