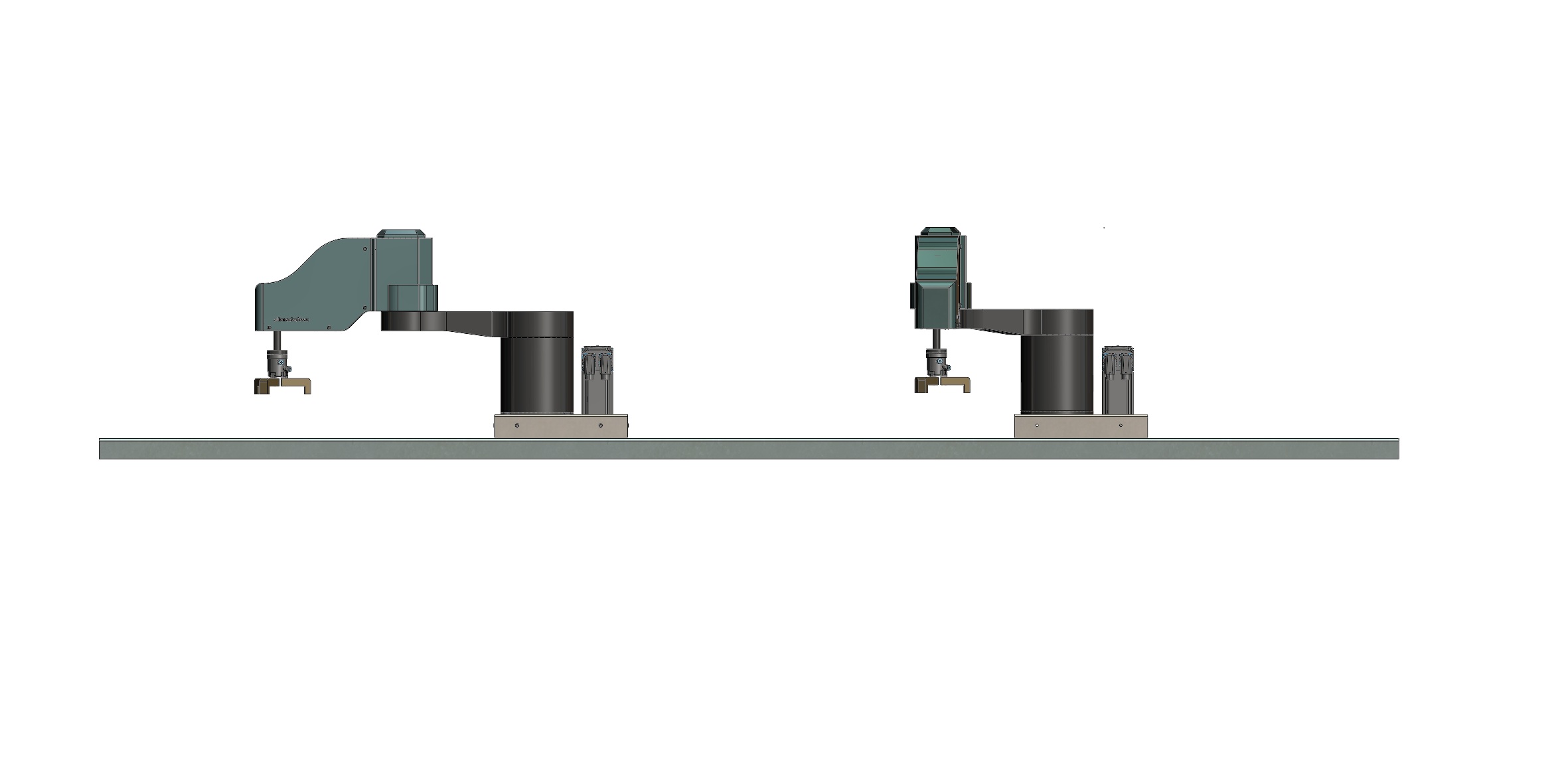

industrial robotic arms

AUTOMATED ROBOTIC GRABBING SYSTEM & ΔΙΑΛΟΓΗΣ

As the world continues to automate to facilitate our lives, the nature of work is changing. The workforce required in factories has significantly decreased because most of the work is now done by machines. In simple terms, human hands are being replaced by robotic hands. Consequently, the robotic arm takes on the weight of manual, repetitive tasks, allowing humans to engage in more critical and safer work. Additionally, automated arms produce better results, reduce injuries, and propel the industry towards the next step, which is full automation. Most importantly, their use has also helped make production processes more efficient and less noisy.

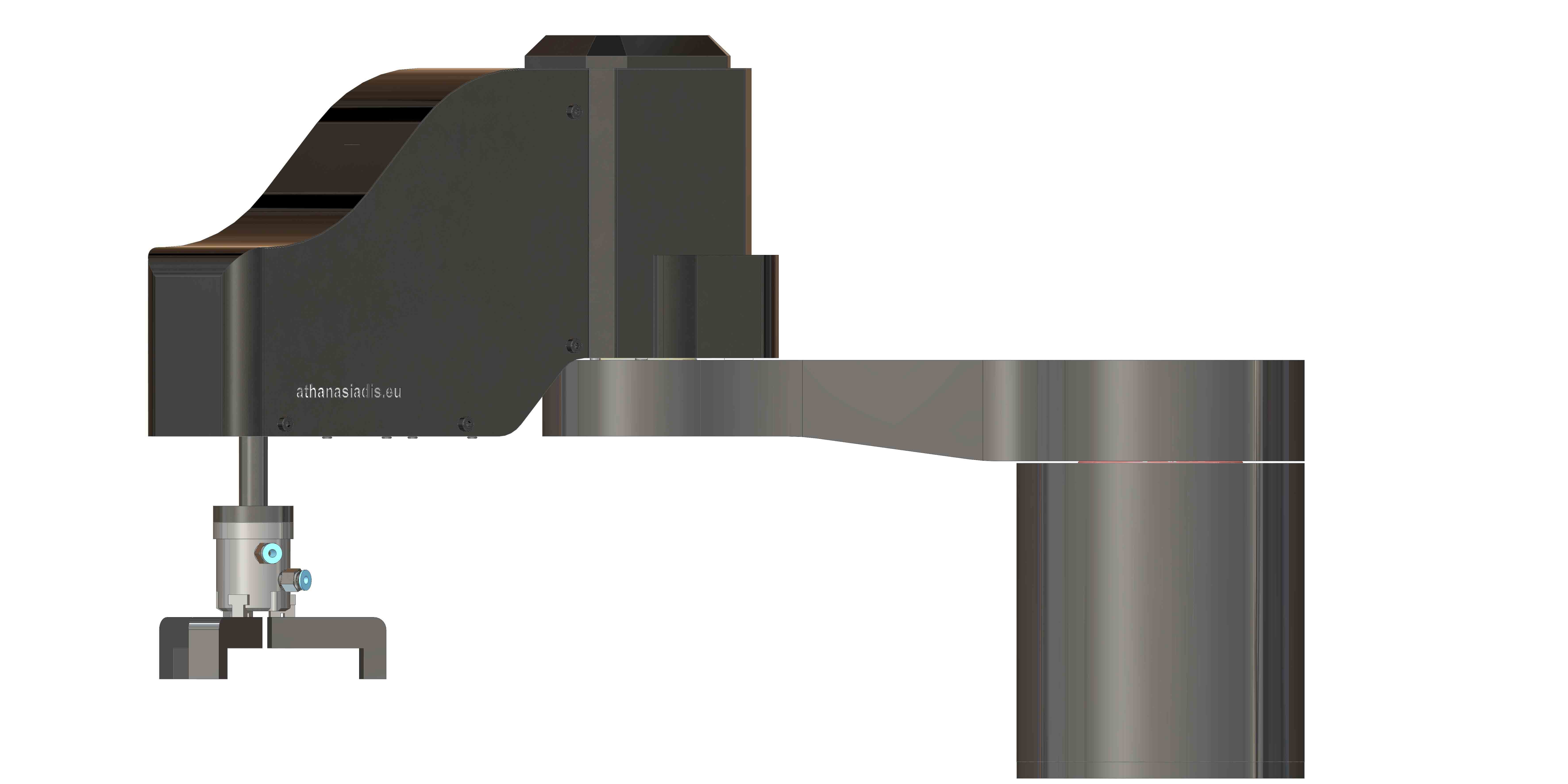

Robotic arms are devices that can be designed in many different ways according to their applications. They heavily rely on joints, which are used to connect the two successive parts in the robot and can be rotational or linear joints. The joints mainly determine the arm's movement as they decide the degree of freedom of the components.

The primary concern of robotic systems is to reduce production cycle time and offer greater flexibility in automation by allowing us to automatically change speeds and control the gripping using servo motors..

ADVANTAGES OF USING ROBOTIC ARMS

Precision

Our arms are equipped with long, slender arms of consistent repeatability. All these enable them to be extremely precise. This high precision capability makes them a good choice for pick and place applications.

Cost-effectiveness

The integration of robotics into the production process can effectively reduce your costs. Robotic precision and reliability allow for less material waste and more efficient use of time. Additionally, the initial investment in robots is quickly recovered, making robotics an extremely cost-effective solution.

Flexibility

Our robots are easily programmable and capable of adapting to multiple changes in the shape and type of the product as we manufacture various types of grippers in collaboration with you. Moreover, they provide a high level of motion flexibility.

Space optimization

Designed with compact mounting bases, our robotics are ideal if you want to save space. The robots can be programmed to move within strict boundaries, leading to even better utilization of your space.

Speed

Robots are suitable for high-speed assembly applications with simultaneous time-saving. Our 4-axis robotic arms, a category generally faster than 6-axis robots, are a top choice for high-speed pick-and-place tasks.

Repeatability

Assembly tasks require a high degree of accuracy, and 4-axis robots generally have better repeatability than other types of robots. Our robotic arms fall into this category, achieving repeatability even in tenths of millimeters (0.1 mm).

Maximizing Safety

Robotic applications are inherently demanding. They usually consist of intense, repetitive, and monotonous tasks. Depending on the weight and size of a component, its movement from one place to another can be very demanding. However, our arms are not affected by application pressures. They can work without breaks or errors.

Consistency

Robotic systems have the ability to improve product quality. Robotic movements are regulated, resulting in consistent results. Consistency improves product quality and allows processes to be performed in the same way, resulting in improvement.