PLASTIC PROCESSING

CAM AND PROCESSING CAPABILITIES

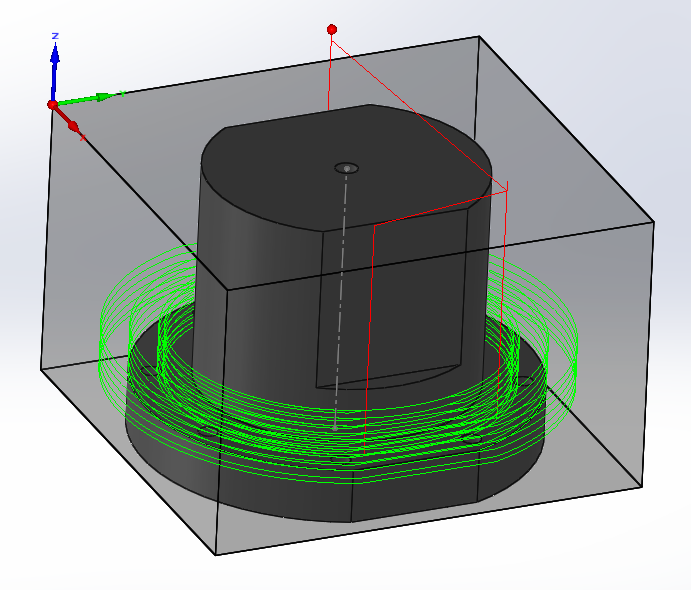

Manufacturing components with the help of a computer, CAM, is the use of software to control machines and related tools during the production of pieces. Our company undertakes the complete implementation of plastic pieces and components made of materials such as polyacetal POM, PVC, polyethylene PE, polystyrene PS, etc., which are intended for arrangements, machines, and molds. After the initial design of the object (CAD) according to the required dimensions, the definition of the processes to be performed on a piece of material follows (CAM). Then, using a CNC machine, material removal takes place to achieve the desired surfaces and dimensions of the piece. The achieved tolerances are sufficient to have assemblies with standardized dimensions and axes.

processing procedure

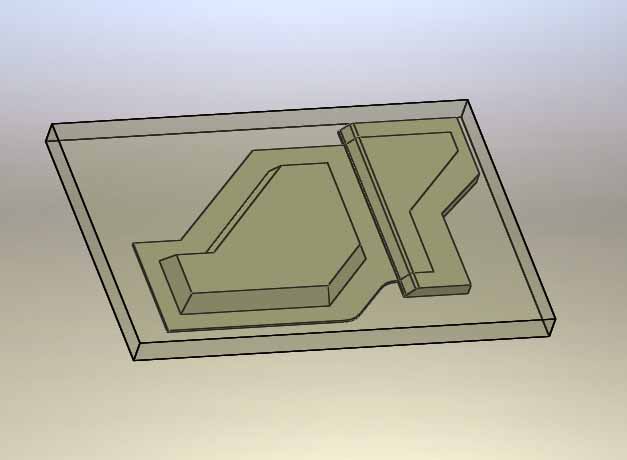

CAD / CAM

Using state-of-the-art 3D CAD/CAM design programs, the product is visualized before production, discussing possible modifications and improvements.

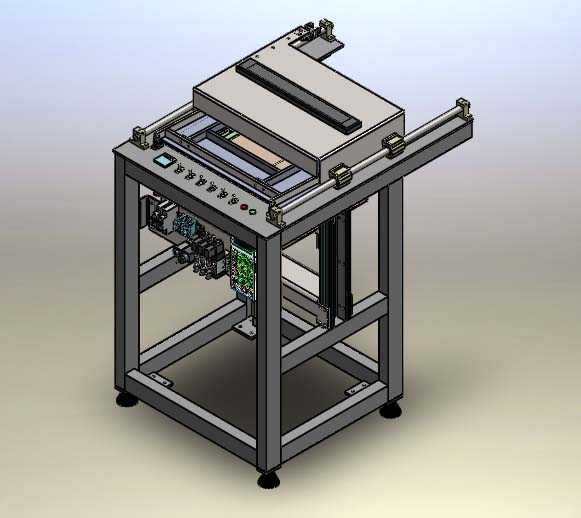

CNC MACHINE

With the use of our self-constructed CNC machine, processing is carried out according to the initial design, and then we complete the construction using a milling machine, lathe, or by opening holes in the piece if necessary.

FINAL PRODUCT

Having a finished product, we check the requirements for the final surface and dimensions and test it for possible assembly with bearings or other components. The product is now ready to be used as a component of an arrangement, machine, or mold.

MOLDING AND THERMOFORMING

MOLD MAKING

We undertake the construction of plastic molds using the design and processing procedure described above. The final products, with accurate dimensions, can be used where necessary and are ideal for the thermoforming process.

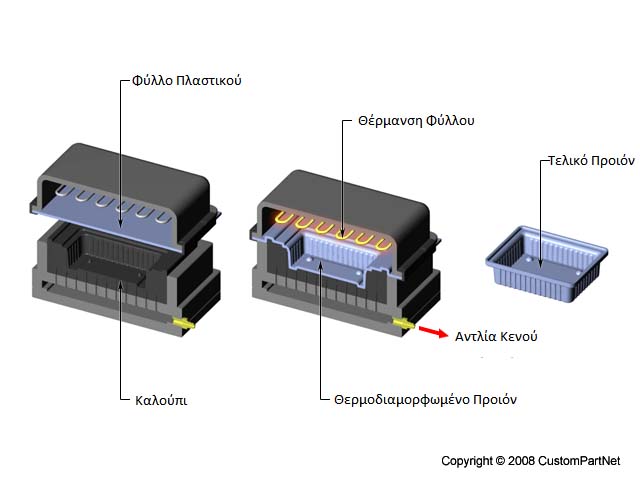

THERMOFORMING

Thermoforming is a process where the heated plastic is drawn over a cold solid mold with the help of vacuum air. When it cools down, the plastic hardens and retains its shape. With our self-constructed thermoforming machine, we can offer you ready-made thermoformed pieces, ideal for caps, containers, etc.